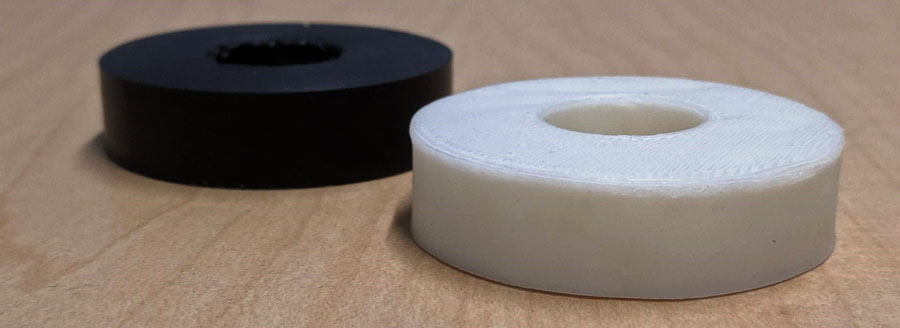

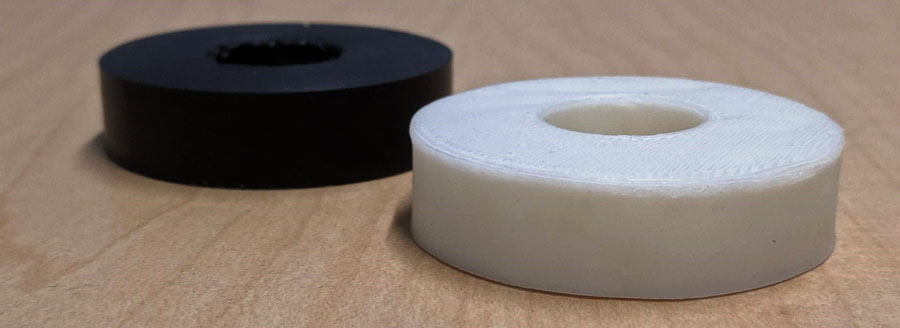

Does Your 3D Project Need Some Material Flexibility?

3D printers can be used to craft almost any item, but the product will fail to work as intended if the wrong material is used. If you plan on making something that needs flexibility, you should avoid using filaments that are made from polylactic acid (PLA) – the most popular kind of 3D printing material. But if PLA doesn’t work, what can you use?

Find the answer in material flexibility with a filament made with elastomers. Elastomers are polymers that have elastic properties due to their weak intermolecular bonds which allow them to stretch without breaking covalent bonds. These properties make filaments made from elastomers an excellent choice for 3D printing projects such as tires, shoe soles, insulating elements, couplings, bands, clips, and more. The most common of these elastomers are thermoplastic polyurethane (TPU), polypropylene (PP), nylon and thermoplastic elastomers (TPE).

Thermoplastic Polyurethane (TPU)

This flexible, abrasion resistant thermoplastic provides excellent layer to layer adhesion offering a durable product. Because of this, the rubber-like elasticity performs well for 3D printed sporting goods, prosthetic parts, footwear, gaskets, etc. There is some work risk, however. 3d printers are not always equipped to handle the extrusion – leading to blobs and stringing. You will need to find the “sweet spot” of temperature, printing speed, retraction and quality product materials such as Terra-Bend™.

Polypropylene (PP)

Polypropylene (PP) is one of the most frequently used and recycled flexible plastic material with usage from pharmaceutical to food-based applications. Companies choose PP because it provides low density while maintaining desired mechanical properties. Because of this, PP finds best usage in food packaging, straps, leashes, etc.

Yet, regardless of its wide-spread usage, it is one of the more difficult materials to work with. The biggest consideration is regarding printing temperatures. Due to its low melting point and semi-crystalline structure, polypropylene cools and solidifies differently than other materials. As a result, parts have difficulty adhering to the print surface and can warp a great deal. Heated enclosures and careful selection of print temperatures can combat these issues. In order to ensure print quality, it is important to consider adhesion properties and follow printing advice from trusted manufacturers such as Terrafilum.

Nylon

Nylon has the best of both worlds by being both flexible and somewhat rigid. PA 12 offers a high melting point and low friction making it perfect for functional applications such as plugs, sockets, clips, and bands. Even with all the functional benefits, working with this material offers a double-edge advantage and challenge. Nylon is very hygroscopic – absorbing moisture from both paints and from the air. This absorption rate is wonderful for aesthetics as it offers a variety of looks upon completion. Yet, the moisture from the air can be a problem prior to completion. For best results, it is recommended to dry the material prior to printing, and vacuum package between prints if possible.

Thermoplastic Elastomer (TPE)

Thermoplastic Elastomers (TPE) are the most popular choice for 3D printing projects needing material flexibility. When used correctly, products made with TPE material can stretch up to double their length then easily return to its original shape due to its rubber-like quality. This quality makes TPE appropriate for anything that needs impact or vibration resistance such as gaskets, couplings, connectors, etc. But be sure to be on the lookout for buckling and plate adhesion as printing too fast with this flexible filament can cause these issues.

Regardless of what material flexibility you need, there are a multitude of aspects to consider. Therefore, it is important to do your research before buying and make sure you are matching the right filament material to the right application. This match will ensure a perfect print every time.

Need help with the next step in deciding a material? Contact one of Terrafilum’s expert consultants to learn more about the benefits of elastomers.