Material Matters: Exploring the Varieties of Cable Coating Materials

Leave a CommentCable coating materials are specialized substances applied to cables to protect them from environmental factors, enhance durability, and improve performance. They are vital in the cable industry, ensuring safety and longevity in various applications. Choosing the appropriate cable coating material is essential, as different cable types and uses demand specific properties for superior functionality and protection.

This article comprehensively compares various cable coating materials, examining their properties, benefits, and environmental impacts. We will also delve into the industry trends towards sustainability and innovation, highlighting how these materials are evolving to meet the industry’s changing needs.

Common Materials Used in Cable Coating

Here are the materials used in cable coatings, detailing their properties, benefits, environmental impacts, and suitability for different cable types:

Polyvinyl Chloride (PVC)

PVC is a flexible and fire-resistant material commonly used in cable coatings. Its chemical resistance and affordability make it popular for general-purpose applications. While PVC contains chlorine, which can release harmful dioxins when burned, it provides excellent insulation. Therefore, they are capable of ensuring the safety of electrical systems in various settings.

Polyethylene (PE)

PE is lightweight, water-resistant, and has good electrical insulating properties. Its moisture resistance makes it ideal for outdoor and underground cables, where exposure to water is a concern. PE’s low toxicity and affordability contribute to its widespread use in the cable industry. This material is also recyclable, which contributes to environmental stewardship efforts.

Cross-Linked Polyethylene (XLPE)

XLPE offers high-temperature resistance, excellent electrical insulation, and superior mechanical strength. This material is suitable for high-voltage power cables. It is designed to withstand high thermal stress, ensuring the reliable transmission of electricity over long distances.

Thermoplastic Elastomers (TPE)

TPEs are flexible, rubber-like materials resistant to extreme temperatures and chemicals. Their excellent flexibility makes them ideal for cables that require frequent bending and movement, such as those used in robotics and automotive applications. TPEs are generally more environmentally friendly due to their recyclability and lower energy requirements for production.

Polyurethane (PUR)

PUR is highly flexible, abrasion-resistant, and resistant to oils and chemicals, making it perfect for industrial cables exposed to harsh conditions. Its durability ensures the cables’ longevity in demanding environments. Careful handling and responsible disposal of PUR help eco-conversation efforts by preventing the risks of toxic chemical contamination.

Trends in Cable Coating Material Options

The cable industry is shifting towards more sustainable and eco-friendly coating materials due to regulatory pressures and a commitment to reducing environmental impact. The following are the key trends in cable coating material choices:

Biodegradable and Bio-Based Polymers

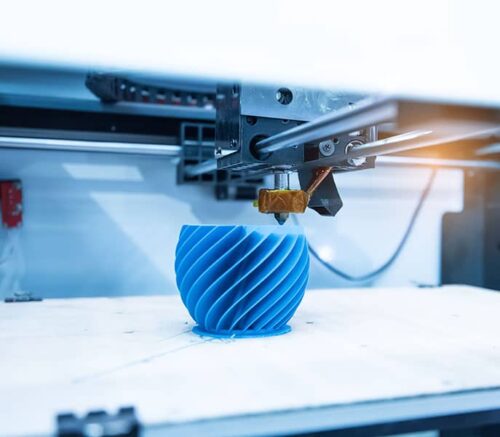

Polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are gaining popularity in the cable industry. They reduce dependence on fossil fuels and offer environmental benefits from renewable sources like cornstarch or sugarcane. Moreover, their biodegradability minimizes ecological impact at the end of their lifecycle.

Halogen-Free Flame Retardants (HFFR)

Materials like polyolefins, magnesium hydroxide, and aluminum hydroxide are increasingly used for safety and environmental benefits. They do not emit toxic gases when burned, making them suitable for enclosed spaces.

Recycled and Recyclable Materials

Options such as PE), polypropylene (PP), and TPE help reduce waste and the need for virgin resources while supporting a circular economy. Using recycled content aligns with growing consumer and regulatory expectations for sustainability.

Low Smoke Zero Halogen (LSZH) Materials

Special polyolefins and EVA copolymers are essential for enhancing safety in cable coatings. They emit minimal smoke and no toxic halogen gases when burned, making them ideal for public buildings and industrial environments. LSZH materials are increasingly required in infrastructure projects due to their safety profile.

Green Coating Technologies

Technologies such as water-based and UV-curable coatings are leading the shift towards environmentally friendly cable coatings. These technologies reduce the use of volatile organic compounds (VOCs), which harm the environment and human health. They also offer quick curing times and energy-efficient processing.

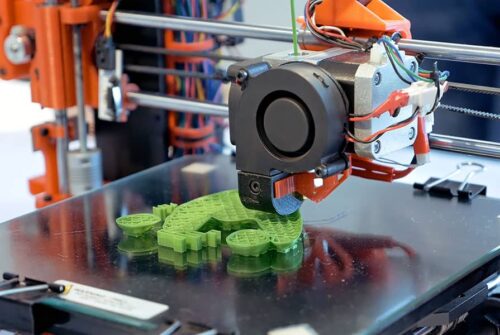

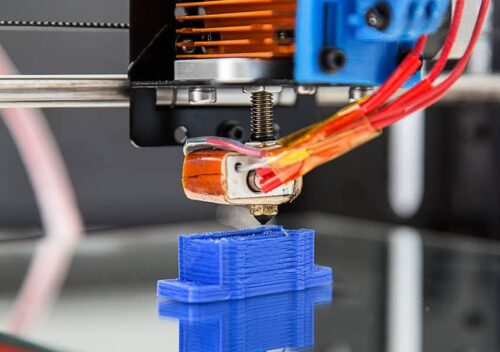

Innovate Your Cable Coatings With Terrafilum’s Cutting-Edge Materials!

At Terrafilum, we understand that choosing the appropriate material matters. We have expanded our capacity to coat steel wire rope using advanced cable coating materials, ensuring premium quality and exceptional performance. With decades of experience, we offer extensive material and coating customization options, making us a trusted source for cable solutions.

Contact us today to learn how we can meet your cable coating needs with our cutting-edge solutions.